Feature

1. The high efficiency charging system has the function of slurry sufficient degassing, material feed rate control and the amount of flocculant. Multi points additive feeding system for max. mixing of additive and slurry. To make good preparation of the slurry flocculantion which improve the flocculant efficiency and economy.

2. The blade of the scraper with a logarithmic spiral distribution is used to scrape the blades of the scraper with the high efficiency and low resistance to run the rotary harrow.

3. PLC control. Overload alarm indicator, auto rake lifting and down,overload motor and hydraulic circuit pressure relief protection to assure the driven device torque wont exceed the rated value. Auto control, manual control and remote control. Long-time lockdowns and trouble can be operated manually and automatically.

4. Control system multi protection

- Oil temperature feedback system.When oil temperature is high the radiator fan will start to work while the temperature is low the heating device will start to work.

- Pressure self test function. Once hydraulic station pressure transformer trouble or damage the machine will turn off automatically and alarm to prevent equipment problem caused by pressure transformer damage

- Remote emergency stop function.Operator can stop the machine immediately once trouble happens.

- Password protection system to prevent operator change the password

Working principle

1. Circular pool body, variable slope bottom or deep cone bottom can achieve deep compression. And variable slope bottom can accelerated the of scraping speed of high efficiency concentration bottom flow to the center. The concentration efficiency improved to 3-8 times of ordinary thickener. The underflow concentration can reach 60-70%

2. The driven device structure is multi hydraulic motor drive central rotary support outer teeth ring synchronously and then drive the main shaft and rake body rotary. It can be adjusted and meet all kinds of condition requirement. When the concentrate pool participate material increased the working resistance of the scraper also increased and the hydraulic system inside pressure also gets high.Once the pressure over the set value, the pressure sensor start to work and open the control valve of the lifting system. When the hydraulic oil goes into the rake cylinder and lift the scrapper, if the resistance keeps increasing the scrapper rake will keeping lifting up. Once the driven pressure over the set value, the thickener will stop automatically with alarm which can protect the main driven system parts. The whole rake lifting action is done by separate rake lifting hydraulic cylinder. All the signal comes from the hydraulic system without affecting by power grid voltage fluctuation. The rake lifting and the lower down work reliable and stable. The max. lifting height is 600mm.

Applications:

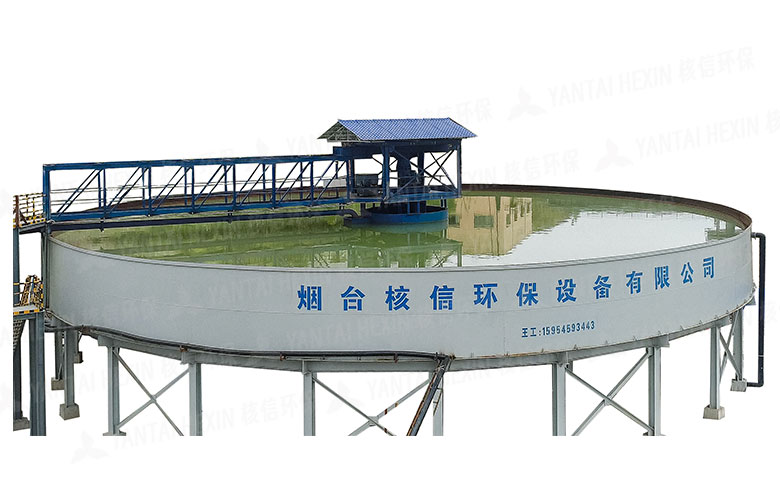

Thickener is a new type of central drive and automatic rake thickener which is developed by our company. It is widely used in many fields such as tailings disposal, hydrometallurgy, environmental engineering, etc.

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail