Feature:

1. Two gravity pre-dehydrate process. High dehydrate speed and the clarity of the filtrate is higher than one gravity process.

2. High continuous automation grade. High single machine process capacity, high dehydrate efficiency and low energy consumption

3. Strong material compatible ability and wide application range.

4. Compact structure, easy operation and convenient maintenance.

5. Advanced filter cloth magnetic control automatic rectify system to correct deflection of the filter cloth at any time which assure the machine stability and reliability.

6. Advanced PLC control which makes the whole machine running stable and reliable, also convenient maintenance.

Brief introduction

BP series belt filter press is a new type of dewatering equipment popular in foreign countries in the 1990s. It has the advantages of continuous operation, high efficiency, low energy consumption and convenient operation. It has been widely used in industrial wastewater such as paper making, textile printing and dyeing, electroplating, petrochemical, tanning, food, etc. and sludge dewatering in urban sewage treatment. It is also widely used in the dewatering of materials in building materials, coal, food and other industries. The BP belt filter press produced by our factory is a new type of belt filter press developed on the basis of borrowing, absorbing and digesting the advanced technology of foreign advanced belt filter presses.

Working principle

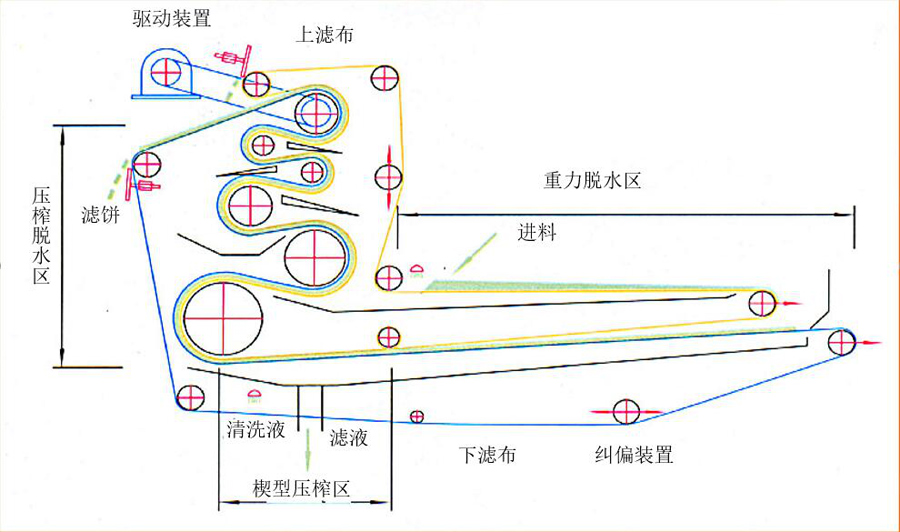

The BP belt filter press is consist of gravity dehydrate area, press area(several roller with different diameter) and upper and lower press belt. It is a kind of high efficiency equipment using the gravity and the repeated press of the roller to cut the material and achieve solid-liquid separation function.The working process and the principle as following:

The material with flocculant was put into flocculation mixer, after mixing sufficiently flows to the gravity pre-dehydrate area. The material is filtered under the gravity. The material moves front with the filter belt after two dehydrate process. (the filter belt is driven by driving device controlled by plc). First enter the “wedge” area to press which will makes the material smooth and dehydrate under the light pressure. The goes to the “S” shape press area. In the “S” shape press area, the material is placed in the middle by the upper and lower filter belt and the material was cut under the repeat pressing of the different diameter roller which makes the material dehydrate. The filter cake after dehydrate was scraped down by the scraper while the filter belt will restart working process after cleaned. The process will carry out continuously and repeatedly.

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail