Feature:

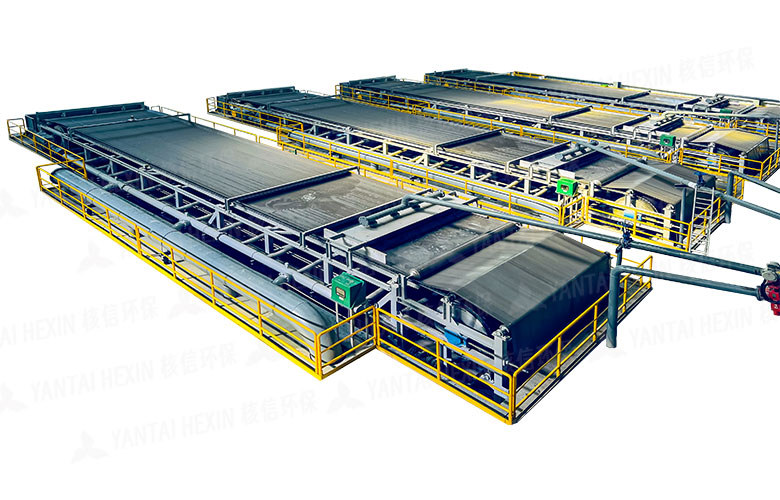

- Modular design, flexible assembling and convenient transportation. It can also be delivered after installation and commissioning.

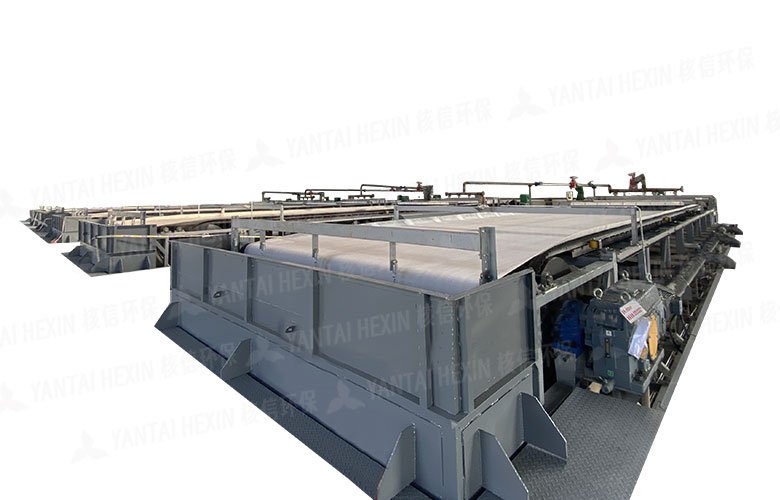

- The filter fabric and the rubber belt runs synchronously which can achieve the function of feeding, filtering, washing, drying and filter cloth regeneration continuously.

- Remote and field interaction control for automatic operation.

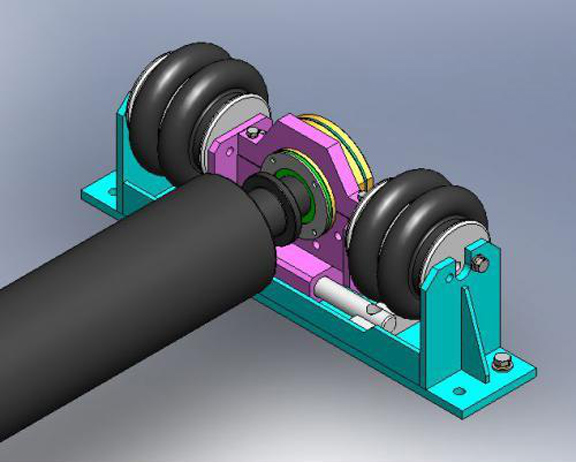

- Various types of rubber belt support methods like roller type, air cushion type, pallet type and multiple friction belt support ways to reduce the friction resistance and increase the rubber belt lifetime.

- Section collection in washing and can be washed in downstream or upstream.

- Optional high-pressure washing way to increase the filter cloth regeneration effect and lifetime.

- Various ways of liquid discharge like zero discharge, high-level discharge and auxiliary discharge.

- Air cover or aluminum plastic window is applied for the semi or fully close which can be used in the materials containing volatile gas or steam partial insulation or centralized collection.

Parameter

|

Width |

|

1.3 |

1.8 |

2 |

2.5 |

3.2 |

4 |

4.5 |

|||||||

|

Length |

N |

Area m² |

Weight T |

Area m² |

Weight T |

Area m² |

Weight T |

Area m² |

Weight T |

Area m² |

Weight T |

Area m² |

Weight T |

Area m² |

Weight T |

|

8 |

3 |

10.4 |

8.3 |

14.4 |

12.7 |

16 |

14.2 |

20 |

20 |

25.6 |

26.3 |

|

|

|

|

|

10 |

4 |

13 |

9 |

18 |

13.7 |

20 |

15.4 |

25 |

22 |

32 |

28.5 |

|

|

|

|

|

12 |

5 |

15.6 |

10.5 |

21.6 |

15.3 |

24 |

17.2 |

30 |

25.3 |

38.4 |

32.9 |

|

|

|

|

|

14 |

6 |

18.2 |

11.5 |

25.2 |

16.6 |

28 |

18.7 |

35 |

27.4 |

45 |

35.3 |

56 |

51 |

63 |

57.9 |

|

16 |

7 |

20.8 |

12.5 |

28.8 |

17.9 |

32 |

20.2 |

40 |

29.5 |

51.2 |

37.7 |

64 |

53.6 |

72 |

60.8 |

|

18 |

8 |

23.4 |

13.5 |

32.4 |

19.2 |

36 |

21.74 |

45 |

31.6 |

58 |

40.1 |

72 |

56.2 |

81 |

63.7 |

|

20 |

9 |

26 |

14.5 |

36 |

20.5 |

40 |

28 |

50 |

38.6 |

64 |

42.5 |

80 |

58.8 |

90 |

72 |

|

22 |

10 |

|

|

39.6 |

21.8 |

44 |

30 |

55 |

40.9 |

70.4 |

51 |

88 |

66.6 |

99 |

75.2 |

|

24 |

11 |

|

|

|

|

48 |

32 |

60 |

43.2 |

77 |

53.5 |

96 |

69.4 |

108 |

78.4 |

|

26 |

12 |

|

|

|

|

|

|

65 |

45.5 |

83.2 |

56 |

104 |

72.2 |

117 |

81.6 |

|

28 |

13 |

|

|

|

|

|

|

|

|

89.6 |

58.5 |

112 |

75 |

126 |

84.8 |

|

30 |

14 |

|

|

|

|

|

|

|

|

96 |

61 |

120 |

77.8 |

135 |

88 |

|

H(m) |

N<5 |

2 |

2 |

2 |

2.18 |

2.6 |

|

|

|||||||

|

5≤N≤9 |

2.18 |

2.18 |

2.18 |

2.38 |

3.1 |

3.1 |

3.1 |

||||||||

|

N>9 |

2.18 |

2.18 |

2.18 |

2.6 |

3.1 |

3.6 |

3.6 |

||||||||

|

W(m) |

|

1.95 |

2.45 |

2.65 |

3.25 |

4.15 |

4.8 |

5.3 |

|||||||

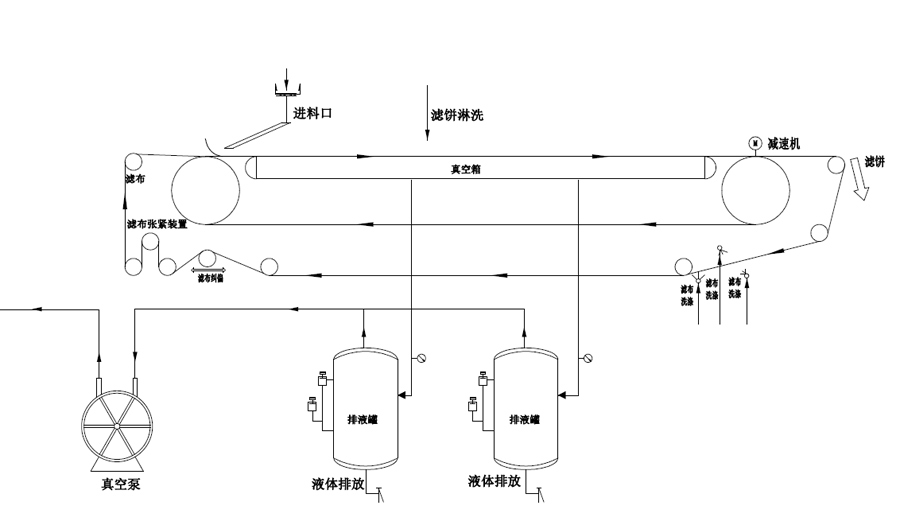

Working principle

The machine adopt fix vacuum box, the cycle rubber belt is driven by the motor and runs continuously on the vacuum box. The filter cloth is layup on the rubber belt and run synchronously. The rubber belt contacted with the friction belt of the vacuum box sliding platform and make water sealing structure.

The slurry is spread on the filter cloth evenly by the distributor. A vacuum suction filtering area is formed when the vacuum room connects with vacuum system. The filtration liquid was collected by the groove of the rubber belt and came into the vacuum room via the holes after crossing the filter cloth. The solid particles was left on the filter cloth and became filter cake. The liquid which comes to the vacuum room was discharged by the air water separator.The filter cake goes into the washing area and washing dry area with the movement of the rubber belt. Finally, the filter cloth separated with the rubber belt and discharge the filter cake at the discharge roller.The filter cloth was regenerated after washing and comes to the filtering area to start a new filter process after a group of support rollers and rectifying devices.

Main Parts

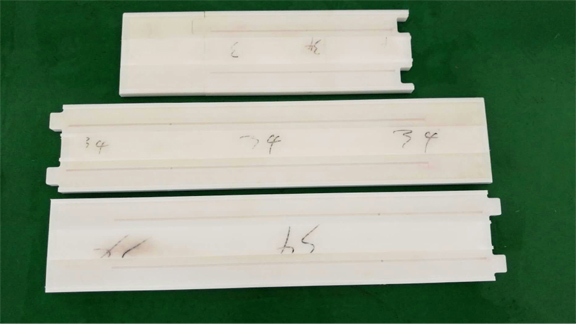

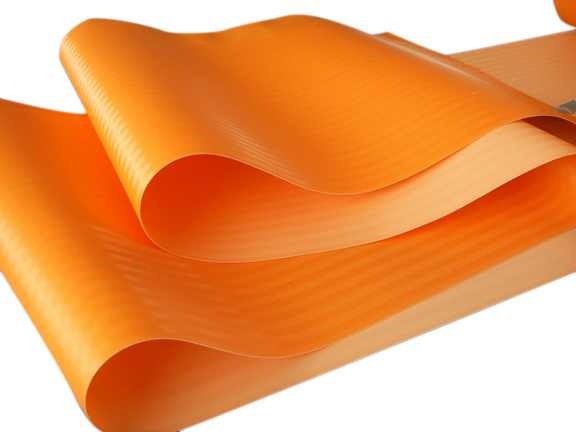

Rubber filter belt

Rubber skirt

Vacuum box

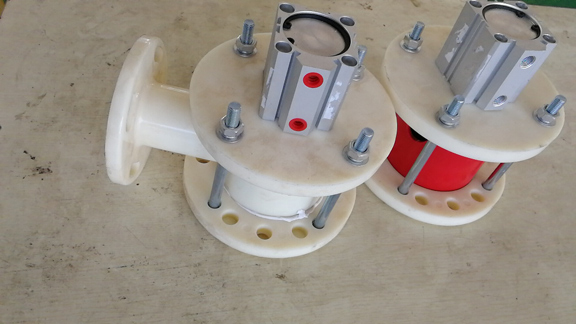

Switching valve assembly

Vacuum slide

Filter cloth

Various types of rollers

Various tanks

Correction device

Control cabinet

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail